|

|

Heavy Duty Warehouse Pallet Racking System Dexion Style Pallet Rack Shelves

|

Product Details:

Payment & Shipping Terms:

|

| Color: | RAL5017、5015(Blue),RAL2004(Pure Orange), RAL1037(Safety Yellow), Or Custom Color As Request | Load Capacity:: | 500kgs~4000kgs/Layer, 4000kgs~30000kgs/Bay |

|---|---|---|---|

| Material: | Q235B/D Steel And Also Q355B/D.High Strength Steel | Surface Treatment:: | Powder Coating /Galv/Hot Dip Galv |

| Color: | RAL5017、5015(Blue),RAL2004(Pure Orange), RAL1037( Yellow), Or Custom Color As Request | Surface Treatment::: | Powder Coating /Galvanized/Hot Dip Galvanized |

| Name: | Heavy Duty Warehouse Storage Racking System | ||

| Highlight: | Dexion Warehouse Pallet Racking System,Warehouse Dexion Pallet Racks,Dexion Style Pallet Rack Shelves |

||

Heavy Duty Warehouse storage Racking System Dexion Style Pallet rack Shelves

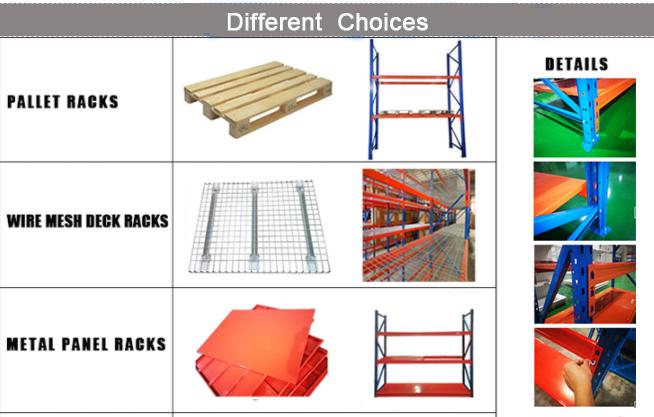

Pallet rack are the most popular, functional racking in the industry. As the best solution for warehouse systems with palletized products, they store a wide variety of goods.

We're specialized in design and production of Pallet Racking and Shelving System, as well as Cantilever Rack, Mezzanine Platform, Radio Shuttle System, ASRS, Wire mesh deck etc.

Advantages

Acerack Storage racking detailed introduction:

| Features | 1. 90% picking efficiency, and appropriate for picking heavy goods by pallet. |

| 2. Surface finishing with araldite static powder coating. | |

| 3. High Strength and durability, easy for complete installation. | |

| 4. Pallets can be located, accessed and moved individually. | |

| 5. Rapid handling of almost all types of palletised goods. | |

| 6. Bottom level of pallets can be stored on the floor, lowering structure costs. | |

| 7. Strength and rigidity prevents compression damage to goods. | |

| 8. Infinitely adjustable and offering a wide range of options and components to accommodate specialized needs. | |

| 9. Maximizes space use in any warehouse configuration while retaining optimum product accessibility. | |

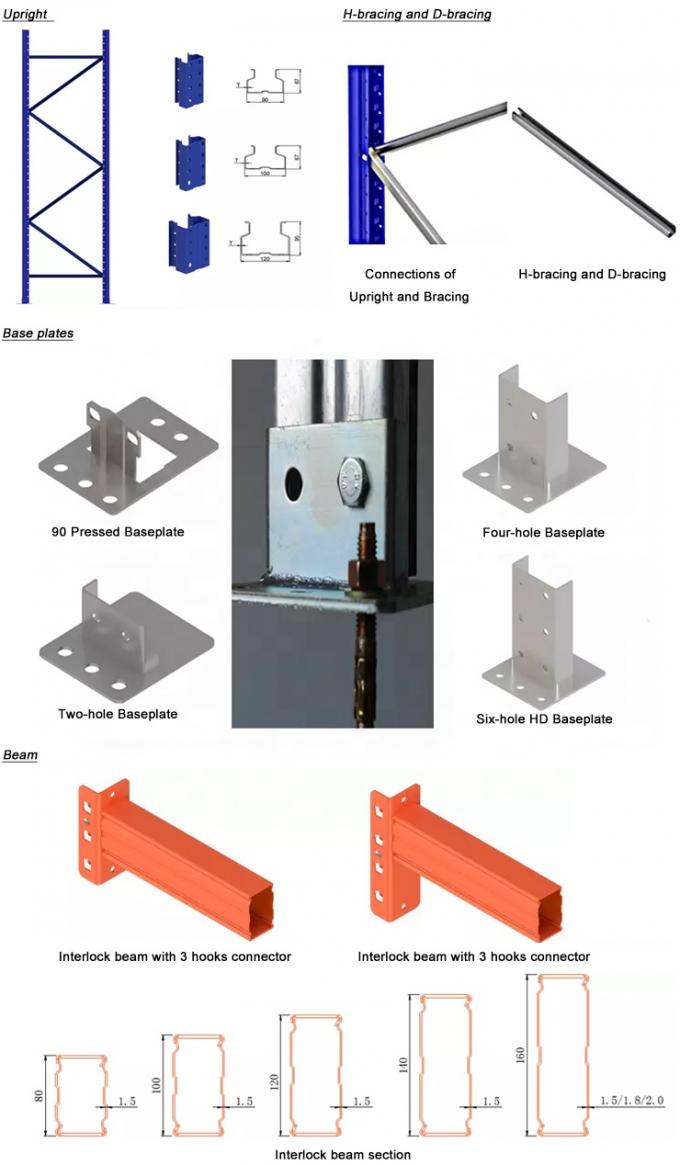

| Beam & Frame | 1. Frame depth normally from 800-1000mm, height is limited by handling equipment of approximate 11mm. |

| 2. Beam length from 1000-3300mm depends on requirement or design. | |

| 3. Operation aisle is from 2200-3800mm depends on operating truck | |

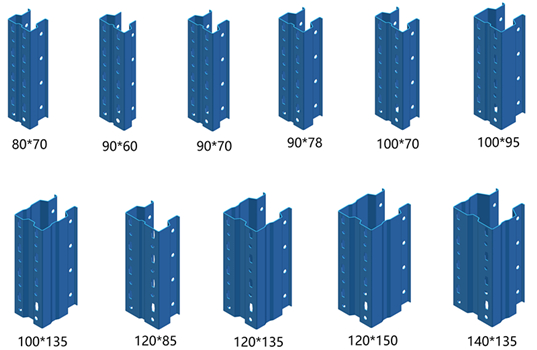

| Main Parts Specs | 1. Upright section: 80*60*2.0, 90*70*2.0, 100*70*2.0, 120*95*2.0-2.5mm, etc. |

| 2. Box beams section: 80*50*1.5, 100*50*1.5, 110*50*1.5, 120*50*1.5-2.0, 140*50*1.5-2.0, 160*50*1.5-2.0, 180*50*2.0mm, etc., | |

| 3. Horizontal & diagonal braces, upright footplates, safety locking pins, bolts & nuts, anchors and all necessary components. | |

| Load Capacity & Dimension | 1. Loading capacity: 500-4,000 kgs UDL/beam level. |

| 2. Height: 1,000-11,000mm | |

| 3. Depth: 400-1,500mm | |

| 4. Length: 1,500-3,300mm | |

| 5. Specail sizes also avaiable to specific storage needs.n to make quick delivery. | |

| Delivery Time | Within 25 days for ordinary order quantity. Big production capacity allows us in a positio |

![]()

![]()

![]()

Standard export package by pallet and covered by plastic film:

![]()

![]()

![]()

![]()

1. Q: Why choose us?

A: Professional design team, adequate production capacity, comply with AS4084. RMI and FEM standard.

2. Q: What is the material on your products?

A: The material normally use is Q235B/D steel and also Q355B/D.

3. Q: What is the packaging of the products?

A: Standard export package by pallet and covered by plastic film.

4. Q: What is the MOQ can order?

A: Normally is one 20ft container, small quantities are also available.

5. Q: What is the payment terms?

A: We accept TT or L/C etc.

6. Q: What is your delivery time?

A: Normally is 2-4 weeks after receipt of the deposit.

7. Q: Are samples available?

A: Yes, we can send some sections of samples for your reference by express.

Contact Person: Lisa

-

Heavy Duty Steel Warehouse Pallet Rack Dexion Standard Style Storage Solution

-

Warehouse Storage Heavy Duty Plastic Crates Stackable Nestable With Attached Lid

-

Dexion Style Warehouse Pallet Racks Steel Storage Solutions Powder Coated

-

Industrial Plastic Stacking Euro Storage Containers Boxes Crates

-

Attached Lid Plastic Storage Crates Stackable Nestable With For Warehouse

-

Steel Warehouse Pallet Rack Heavy Duty Selective Pallet Rack Dexion Standard Style